Project Details

- Product Name:

Nanometer Modified Diamond Powder

- Usage:

Used for Brazing, Powder Metallurgy, Cutting Tool, Wire Saw, Sand Saw, etc.

- Technology:

CVD HPHT

Material Properties

① By application of Aerospace Material and Nanometer Modification Technology

② Binding Degree of Diamond and Metal ≥400MP

③ Adhesion Degree can be improved 0.5-1 times, compared with traditional

④ Brazing Diamond in Air

⑤ Manufacturing diamond high heat conduction material

Nanometer Modified Diamond Powder (NMDP) is a versatile material that can be used for a variety of applications. This article provides a basic understanding of the properties of this material and the key applications for this unique material. It also discusses physicochemical and antifouling properties.

Characteristics of Nanometer Modified Diamond Powder

- Nanometer-modified diamond powders have different physicochemical properties than the unmodified diamond powders. These modifications were achieved by UV illumination or electron beam irradiation. Both processes result in an increase of the surface free energy and a decrease in the water repellency. However, diamond particles exhibit weaker wettability modifications than ZnO powder.

- UV treatment weakly alters the surface free energy of diamond powder. The amount of dispersive energy decreases from 24.5 to 24 mJ/m2, while the amount of polar energy increases from 8.5 to 13 mJ/m2. Electron beam treatment increases the surface energy of diamond particles.

- In order to determine the effects of nanodiamonds on nanostructure and lubricant, we analyzed the thermal and structural properties of nanodiamonds in water. These results suggest that nanodiamond particles with negative charge are more stable in aqueous dispersion than those with positive charge. This suggests that nanometer-modified diamond particles can be designed to retain the desired functionalities of lysozymes.

Nanodiamonds exhibit excellent biocompatibility and are easily incorporated into cells. They can be used as diagnostic probes, antiviral agents, and tissue scaffolds. In addition, they have excellent electrochemical properties. Their high stability and low background current make them ideal for electrode applications.

Gemological properties of Nanometer Modified Diamond Powder:

Nanometer-sized diamond powders can be produced by a synthesis process using high temperature and static ultra-high pressure. They are then crushed and the size is reduced to a few nanometers. The particle size is then compared to a particle size distribution and the particle magnification is measured.

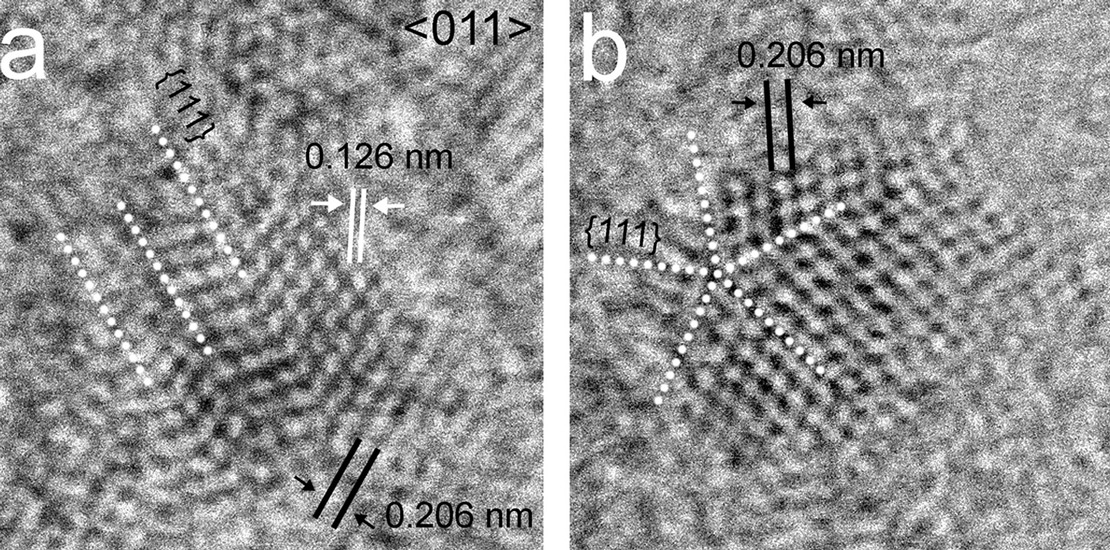

Diamonds of this size are called poly-crystalline because they are composed of secondary particles sized above 100 nm. They are formed from primary particles that have defects and are formed under extremely high pressure. These primary particles are typically spherical and have short loading times. They aggregate together to form the secondary diamond particles.

The resulting diamond slurry is cooled and a small portion of nitric acid is added to the slurry. The resulting diamond particles are then deposited in agglomerates, which are then dried at 120 degrees C. These diamonds are then used in a variety of applications.

Nano-sized diamond particles are non-toxic and are well tolerated by the human body. Therefore, future medical uses of nano diamonds are likely. In addition to its medical uses, nano-sized diamonds can be used as a filler in synthetic materials. They are also used as friction-reducing elements in bicycle chains. Industrial wastewater treatment facilities are also using diamond nanoparticles to clean water.

Nanometer-sized diamond particles are also useful bio-object probes. Because they are biocompatible, nanodiamonds can be used to label live cells and other bio-objects. The nanodiamond particle’s fluorescent centers make them ideal fluorescent imaging markers. Moreover, nanodiamond particles are able to penetrate cells and thus provide a spectroscopic signal.

Nanometer Modified Diamond Powder Nanometer Modified Diamond Powder:

Nanodiamonds exhibit excellent biocompatibility and are easily incorporated into cells. They can be used as diagnostic probes, antiviral agents, and tissue scaffolds. In addition, they have excellent electrochemical properties. Their high stability and low background current make them ideal for electrode applications.

These findings support the idea that diamond powders can be treated with low-energy electrons. However, the main problem remains that their intrinsic inertness cannot be altered. Therefore, the only option is to remove the impurities or replace them with modified ones.

In this paper, we describe surface fluorination of nanometer-modifed diamond powder. We found that a combination of o-dichlorobenzene and 3-aminopropyltriethoxysilane can produce diamond powders with a new component at the C1s core level, and that the resultant diamond particles are bonded to the glass surface by a covalent bond.

Fluorescent diamonds can be used for a variety of applications. They can act as biomarkers for diagnosis and drug delivery. They can also be used to generate color centers from the nitrogen in the diamond core. These centers emit light in the red wavelength range, and are extremely photostable. Furthermore, they do not exhibit photoblinding.

Surface fluorination of nanometer-moderated diamond powder is a highly efficient process to prepare functional nanodiamonds. Surface fluorination is accomplished by treating NDs with reactive gases, which achieve a high degree of oxidation. This process also results in the formation of hybrid nanoparticles, which consist of a diamond core surrounded by sp2 reconstructions.

Fluorination is an important step in the fabrication of nanodiamonds. It enables nanodiamonds to be tuned over a wide pH range.

Nanometer Modified Diamond Powders (NDs) are carbon nanomaterials that exhibit diamond crystalline structure and have crystal defects on their surface. They have been shown to decrease fouling and increase the number of active sites on electrodes. However, the specific electrochemical properties of these particles are unknown. The present study aimed to investigate their antifouling properties in nanoscale environments. Nanodiamond suspensions were drop-casted onto carbon-fiber microelectrodes and showed a reduction of biofouling and chemical fouling.

The study was performed at the NASA Lewis Research Center and involved the use of a method that synthesizes nanometer diamond particles. These particles have a grain size of four to eight nm and a specific surface area of 250-300 m2/g. They have spherical morphology and exhibit better properties than traditional electroless diamond composite coatings. The preparation and properties of Ni-P-ND coatings were also described. They showed better tribological performance than Ni-P coatings.

Another application for these products is in the production of machine tools. They can last 10 times longer than conventional tools. The films are able to resist wear and corrosion. They can also be used as protective coatings on optical instruments and other products. Diamonex plans to introduce its first commercial product in the late 1990s.

The antifouling properties of Nanometer Modified diamond powder have been studied for a variety of purposes. They have been used to coat solar cells and to prevent the formation of fouling. They are also used as antireflective coatings. Moreover, they can enhance the optical band gap. Their optical properties have been studied by FTIR and Raman spectroscopy.

Nanometer Modified Diamond Powder (NMDP) exhibits biofouling resistance and wetting properties. It also exhibits a good adhesion to biomaterials. The researchers developed a thermal anchoring technique to precisely control the surface properties. The resulting nanodiamonds are suitable for the study of biofouling resistance and wetting properties of polymers.

Biofilms are formed by bacteria adhering to surfaces. These biofilms increase in thickness and can impair the filtration capacity of membranes. Additionally, dissociated bacterial cells from mature biofilms can attach to other surfaces and pose a risk to downstream processes. Biofilms also serve as an excellent source of nutrients for embedded bacterial cells, protecting them from environmental stresses.

Biofouling of SPK membranes was effectively mitigated by the SPK anti-biofilm layer. This layer was stable in synthetic wastewater and can be released for regeneration in pH 10 solution by reloading fresh particles onto the membrane. Besides, the anti-biofouling layer significantly improved filtration fluxes and reduced the extent of biofouling and bacterial coverage on the membrane.

Nanometer Modified Diamond Powder (NMDP) can inhibit biofouling by reducing the fouling of electrodes. Its antifouling properties also depend on the degree of ND surface coverage on electrodes. When electrodes are coated with fewer drops of ND, biofouling is reduced significantly. This result indicates that the use of NDs can reduce biofouling while maintaining enhanced electrochemical signals.

Related Projects

lab grown diamonds

Nanometer Modified Diamond Powder

lab grown diamonds

CVD SC Diamond Optical Window

lab grown diamonds